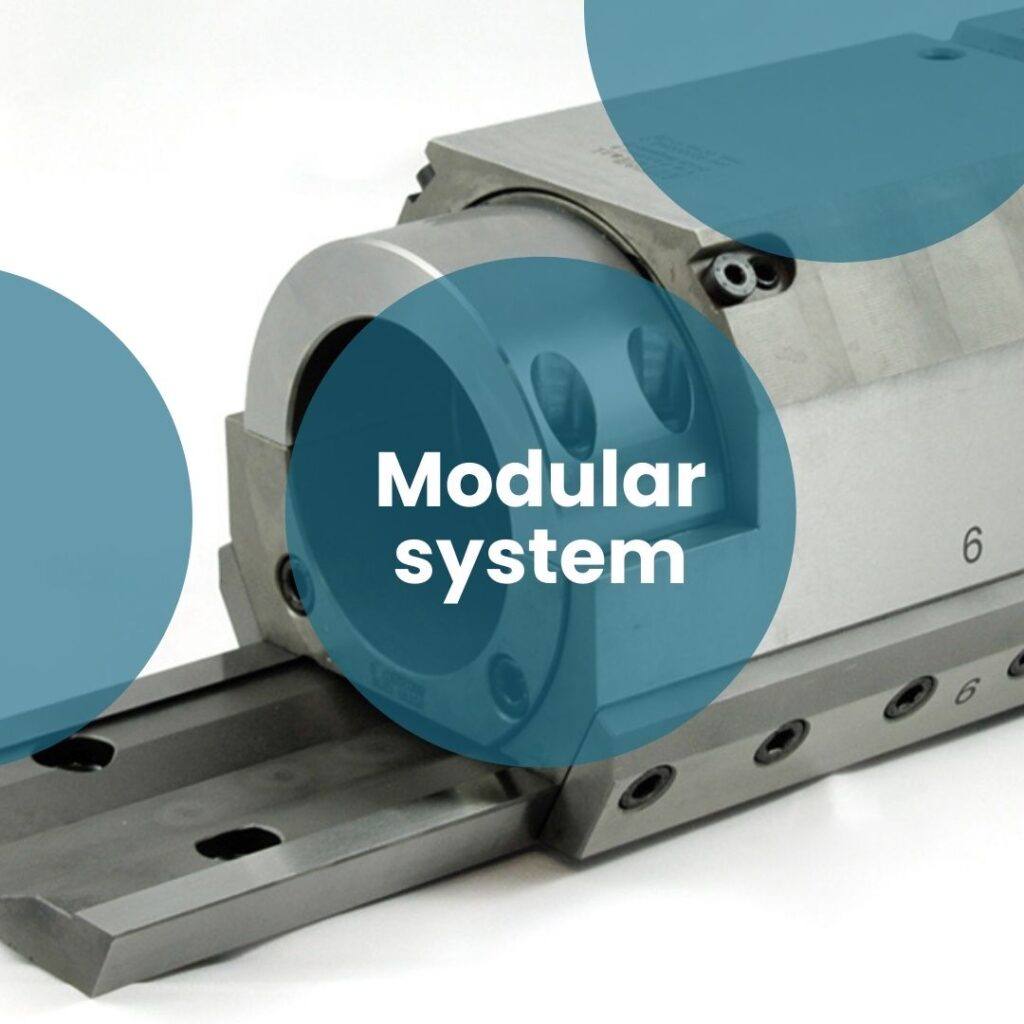

In the world of industrial machining, reducing set-up time and increasing operational flexibility are key factors for optimizing productivity. Autor s.r.l. has developed a modular system for tool spindles, an innovative solution designed for multi-spindle lathes that allows the installation of several standard devices with a unique dedicated adaptation.

Why Choose the Autor Modular System?

Thanks to its innovative structure, the modular system for multi-spindle lathes enables the rapid replacement of the front accessory by simply removing a flange secured with just two screws. This allows operators to switch configurations in a matter of moments, without having to disassemble entire machine components, drastically reducing downtime and boosting production efficiency.

A solution for every need

With the Autor modular system, your company will have the ability to perform different operations without investing in new equipment. Accessories that can be installed include:

- Tool spindle, non rotative – for precision operations requiring maximum stability

- Rotating tool spindle – ideal for high-speed machining or tapping

- High-speed drilling spindle – for small-diameter drilling tasks

- Frontal rotating milling unit – for advanced milling operations

- Eccentric front drilling unit – for special operations requiring eccentric drilling

- U-axis – for advanced internal or external machining with CNC-controlled tool movement

- Synchronous broaching unit – perfect for high-precision broaching applications

Compatible with various Multi-spindle Lathes

One of the key features of the Autor modular system is its universal compatibility. Modular accessories can be used on different models and brands of multi-spindle lathes, thanks to a dedicated adaptation. This ensures simple and immediate integration, thus expanding the possibilities of use and optimizing existing machinery with no need for new toolings.

All the advantages of the Autor Modular System

Thanks to Autor’s modular system, your company will be able to optimize production processes, reduce setup times, and improve machining quality, thus increasing competitiveness.

Furthermore, presetting capabilities allow accessories to be configured before installation, further minimizing machine equipment downtime. The universal compatibility ensures each accessory can be used across various models and setups of multi-spindle lathes.

The modular system comes standard with Autor’s AGM 635 and AGM 620 Automatic Multi-spindle Lathes, delivering a cutting-edge setup ready to meet any production challenge.